Durmapress Press Brakes

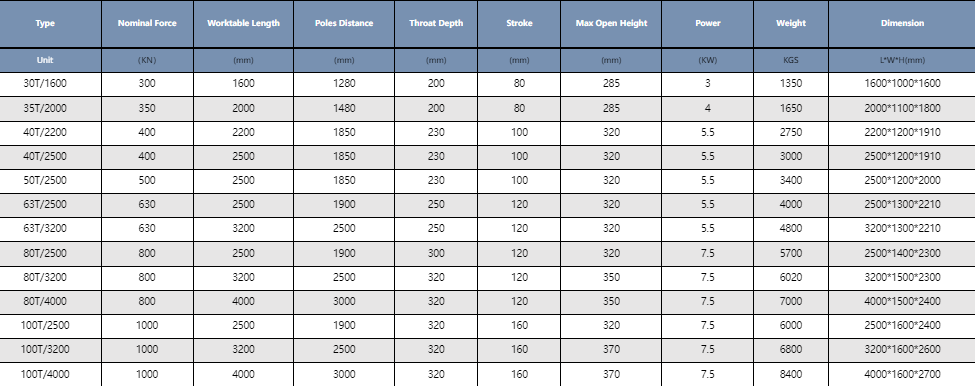

TECHNICAL PARAMETERS

GENERAL FEATURES

E21 NC Controller From ESTUNController Data

| |||

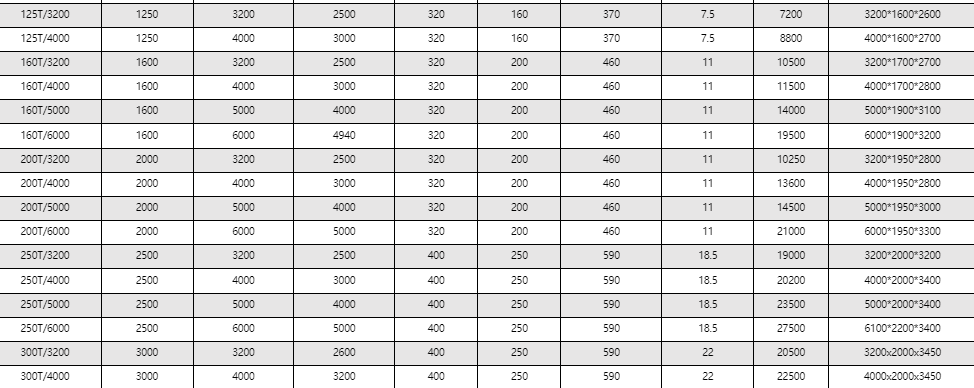

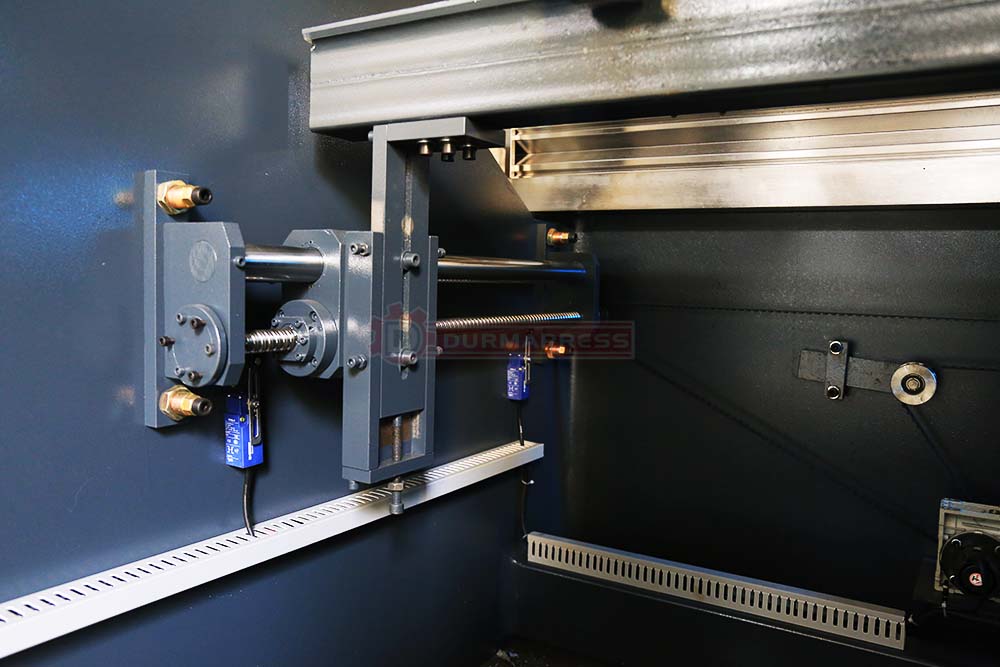

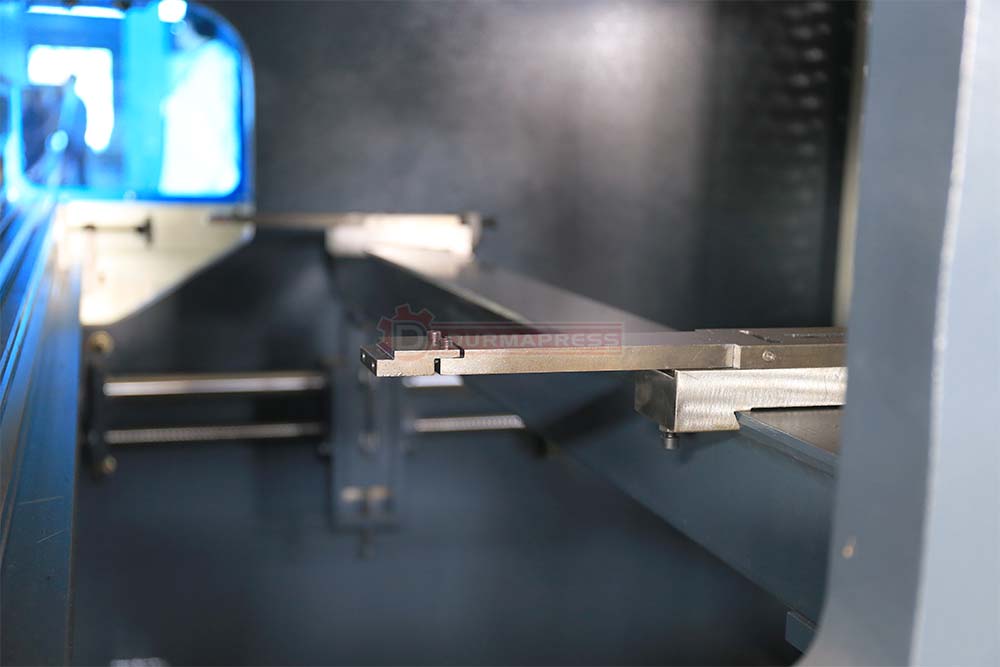

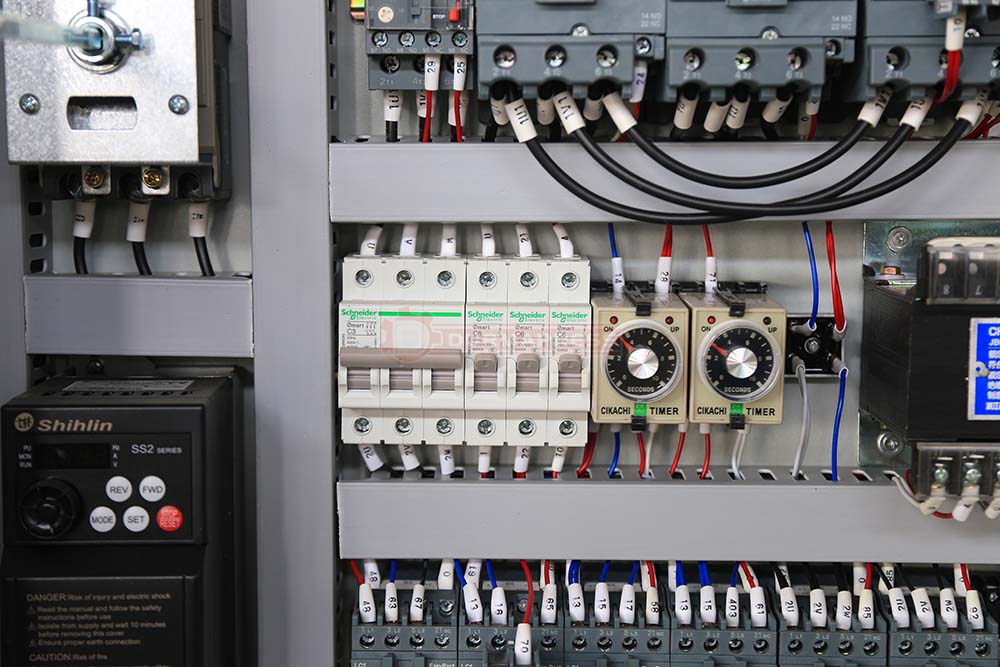

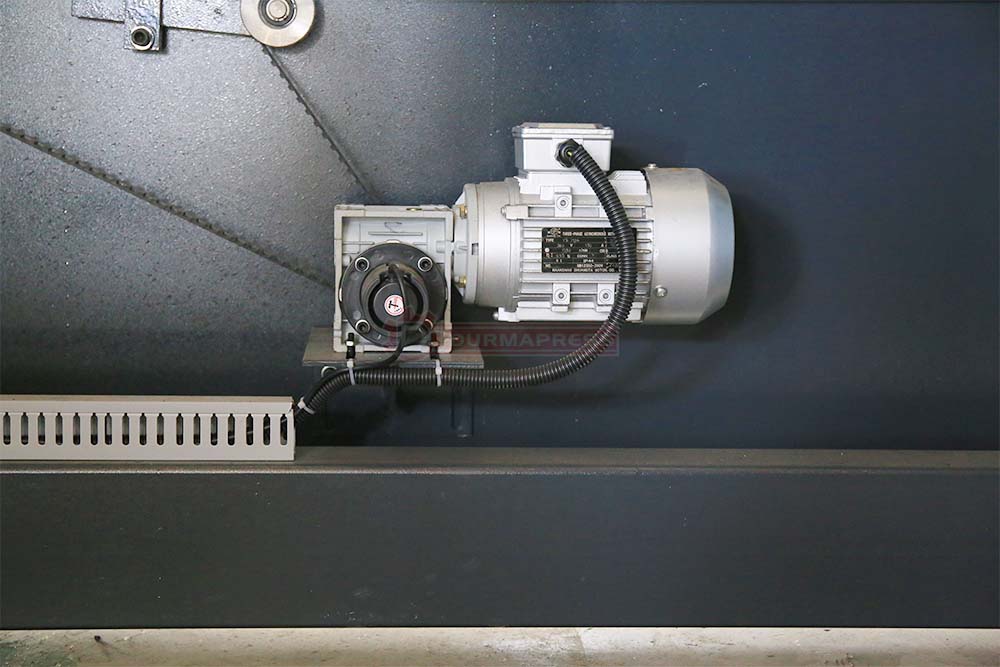

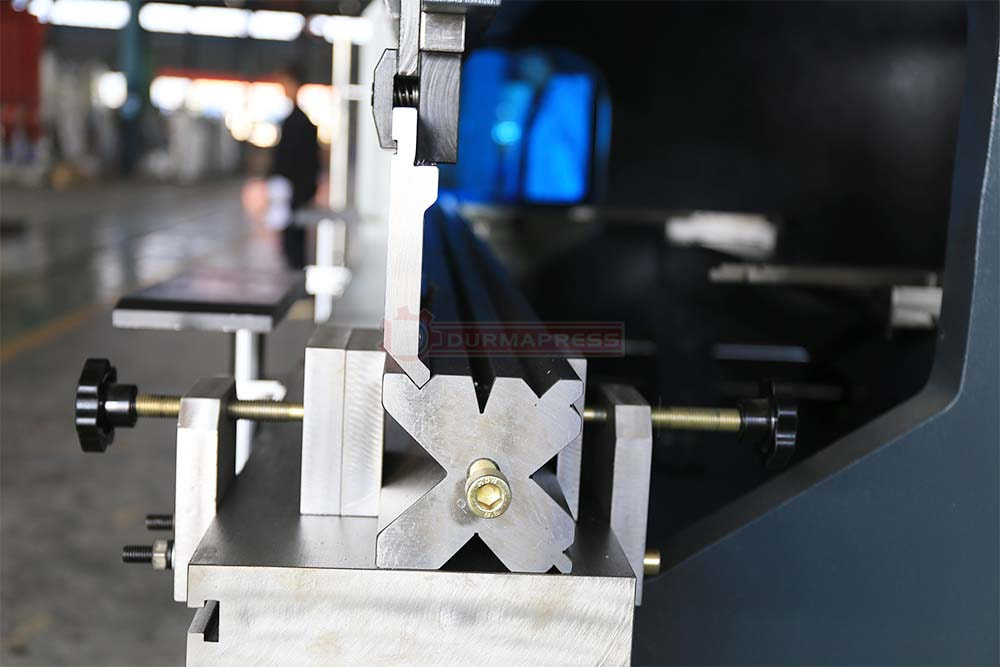

MAIN COMPONENTS

|

Machine BodyThe foundation of every Durmapress press brake is a solid, mono-block frame which made from high yield steel. Which means our press brakes will perform accurately and reliably year after year.

Every press brake frame is tempered. Contact us for full quotation |

OTHER COMPONENTS

|

Video of machine working

|

WC67K Press Brake Operation

Matters needing attention when bending:

|